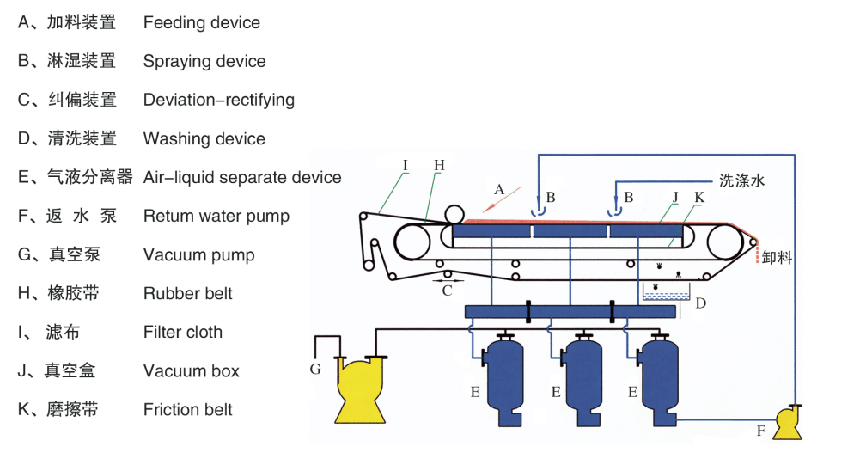

气缸纠偏 Cylinder correction

|

气囊纠偏 air bag correction |

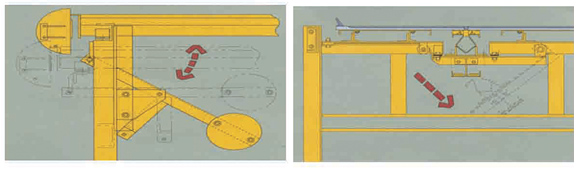

| 胶带张紧装置 Tape tensioning device 采用螺杆推拉式设计,轴承座选用滑槽式。螺杆顶部带摇柄轮,通过转动摇柄可以对橡胶过滤带进行张紧和调偏。 Screw push-pull design, bearing seat selection of chute type. The top of the screw is equipped with a crank wheel, and the rubber filter belt can be tensioned and deflected by rotating the crank.  |

清洗装置 Cleaning device 采用水喷射清洗滤布和过滤带,且配有密封的箱体,清洗管进出的两侧采用法兰密封,这样可以保证清洁的工作现场和过滤机的正常工作。喷头采用本公司自制喷嘴,可以充分保证清洗效果。 Using water jet cleaning filter cloth and filter belt, and equipped with a sealed box, both sides of the cleaning pipe inlet and outlet are sealed with flanges, which can ensure a clean work site and the normal work of the filter. The nozzle is made by our company, which can fully guarantee the cleaning effect.  |

| 张紧装置 Tape tensioning device |

清洗装置 Cleaning device |

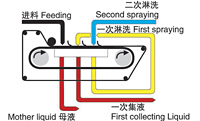

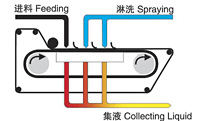

| 淋洗工艺 Spindle roller support 采用逆流淋洗与喷淋洗装置,同时可根据物料及工艺的要求采用顺流洗涤和逆流洗涤两种方法,对物料清洗的更彻底。 The use of counter-current washing and spray washing device, at the same time according to the requirements of the material process can be used in the downstream washing or counter-current washing coating method, the material cleaning more thoroughly. |

|

逆流洗涤示意图

Schematic representation of the countercurrent wash |

顺流洗涤示意图 Schematic representation of the downstream wash |

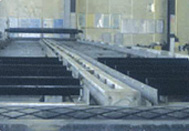

| 胶带支撑装置Tape support device 材质采用塑料合金,具有高耐磨性、抗冲击性、自润滑性等特性。轴承室和密封圈材质为一次性注射成型的全塑材料,并采用迷宫式和接触式三层防水、防尘密封支撑装置。密封材料选用日本BPT-G塑料,使用不变形,有效预防轴承的锈蚀,与原来普遍采用的钢制托辊相比,具有重量轻、耐腐蚀、密封性好、不进水、不怕粉尘、抗冲击、高速运行噪音低、耐磨耗、使用寿命是钢制托辊的三倍以上等显著优点。 The material is made of plastic alloy, with the characteristics of high wear resistance, impact resistance, self-lubrication and etc. The bearing chamber and sealing ring are made of disposable injection molding all-plastic material, supported by labyrinth and contact three-layer waterproof and dust-proof sealing devices. The sealing material is made of Japanese BPT-G plastic, which does not deform and effectively prevents the corrosion of bearings. Compared with the steel rollers commonly used in the past, it has the obvious advantages of light weight, corrosion resistance, good sealing, water-proof, dust-proof, impact resistance, low noise of high-speed operation, abrasion resistance, and service life is more than three times that of steel rollers. |

|

心轴托辊支撑 |

控制系统 Control system |

| 控制系统Control system 采用变频调速控制系统,实现带机速度自由给定。并根据客户的需求,可搭载自动运行和自动保护通讯控制系统系统,实现纠偏控制、胶带极限位置控制(停机、节点信号输出)、滤布拉断控制(停机、节点信号输出),远程和现场开、停机及主控机转速输出至DCS系统的通讯接口。控制系统元件采用国外进口件和国内知名品牌产品,质量稳定可靠,系统控制稳妥实用。 Frequency conversion speed control system is adopted to realize the free setting of the speed of the tape machine. And according to customer needs, it can be equipped with automatic operation and automatic protection communication control system system, so as to achieve deviation correction control, tape limit position control (stop, node signal output), filter bra break control (stop, node signal output), remote and field open, shut down and control machine speed output to the DCS system communication interface. The control system components are imported from abroad and well-known domestic brand products, with stable and reliable quality. The system control is stable and practical. |

|

控制系统Control system |

控制系统Control system |

| 过滤宽度/M Filter Width |

1.3 | 1.8 | 2.0 | 2.5 | 3.2 | 4.0 | 4.5 | |||||||||

| 过滤长度/M Filtering Length(mm) |

N(整数) | 过滤面积/m2 | 重量/T | 过滤面积/m2 | 重量/T | 过滤面积/m2 | 重量/T | 过滤面积/m2 | 重量/T | 过滤面积/m2 | 重量/T | 过滤面积/m2 | 重量/T | 过滤面积/m2 | 重量/T | |

| 8 | 3 | 10.4 | 8.3 | 14.4 | 12.7 | 16 | 14.2 | 20 | 20.0 | 25.6 | 26.3 | |||||

| 10 | 4 | 13.0 | 9.0 | 18.0 | 13.7 | 20 | 15.4 | 25 | 22.0 | 32.0 | 28.5 | |||||

| 12 | 5 | 15.6 | 10.5 | 21.6 | 15.3 | 24 | 17.2 | 30 | 25.3 | 38.4 | 32.9 | 40 | 48.0 | 54 | 55.0 | |

| 14 | 6 | 18.2 | 11.5 | 25.2 | 16.6 | 28 | 18.7 | 35 | 27.4 | 45.0 | 35.3 | 56 | 51.0 | 63 | 57.9 | |

| 16 | 7 | 20.8 | 12.5 | 28.8 | 17.9 | 32 | 20.2 | 40 | 29.5 | 51.2 | 37.7 | 64 | 53.6 | 72 | 60.8 | |

| 18 | 8 | 23.4 | 13.5 | 32.4 | 19.2 | 36 | 21.7 | 45 | 31.6 | 58.0 | 40.1 | 72 | 56.2 | 81 | 63.7 | |

| 20 | 9 | 26.0 | 14.5 | 36.0 | 20.5 | 40 | 28.0 | 50 | 38.6 | 64.0 | 42.5 | 80 | 58.8 | 90 | 72.0 | |

| 22 | 10 | 39.6 | 21.8 | 44 | 30.0 | 55 | 40.9 | 70.4 | 51.0 | 88 | 66.6 | 99 | 75.2 | |||

| 24 | 11 | 48 | 32.0 | 60 | 43.2 | 77.0 | 53.5 | 96 | 69.4 | 108 | 78.4 | |||||

| 26 | 12 | 65 | 45.5 | 83.2 | 56.0 | 104 | 72.2 | 117 | 81.6 | |||||||

| 28 | 13 | 89.6 | 58.5 | 112 | 75.0 | 126 | 84.8 | |||||||||

| 30 | 14 | 96.0 | 61.0 | 120 | 77.8 | 135 | 88.0 | |||||||||

| A(m) | N<5 | 0.20 | 0.20 | 0.25 | 0.25 | 0.40 | ||||||||||

| N≥5 | 0.25 | 0.25 | 0.25 | 0.40 | 0.40 | 0.40 | 0.40 | |||||||||

| B(m) | N<5 | 0.45 | 0.45 | 0.45 | 0.45 | 0.52 | ||

| N≥5 | 0.45 | 0.45 | 0.45 | 0.52 | 0.645 | 0.645 | 0.645 | |

| C(m) | N<5 | 1.30 | 1.30 | 1.30 | 1.30 | 1.60 | ||

| 5≤N≤9 | 1.30 | 1.30 | 1.30 | 1.60 | 1.675 | 1.675 | 1.675 | |

| N>9 | 1.30 | 1.30 | 1.60 | 1.675 | 1.975 | 1.975 | ||

| D(m) | N<5 | 2.00 | 2.00 | 2.00 | 2.00 | 2.20 | ||

| 5≤N≤9 | 2.00 | 2.00 | 2.00 | 2.00 | 2.20 | 2.20 | 2.20 | |

| N>9 | 2.00 | 2.00 | 2.20 | 2.20 | 2.25 | 2.25 | ||

| E(m) | N<5 | 1.85 | 1.85 | 2.00 | 2.00 | 2.11 | ||

| 5≤N≤9 | 2.00 | 2.00 | 2.00 | 2.11 | 2.21 | 2.21 | 2.21 | |

| N>9 | 2.00 | 2.00 | 2.11 | 2.21 | 2.41 | 2.41 | ||

| F(m) | N<5 | 0.86 | 0.86 | 0.86 | 0.86 | 1.105 | ||

| N≥5 | 0.91 | 0.91 | 0.91 | 1.105 | 1.205 | 1.205 | 1.205 | |

| H(m) | N<5 | 2.00 | 2.00 | 2.00 | 2.18 | 2.60 | ||

| 5≤N≤9 | 2.18 | 2.18 | 2.18 | 2.38 | 3.10 | 3.10 | 3.10 | |

| N>9 | 2.18 | 2.18 | 2.18 | 2.60 | 3.10 | 3.60 | 3.60 | |

| W(m) | 1.95 | 2.45 | 2.65 | 3.25 | 4.15 | 4.80 | 5.30 |

| 物料名称 | 液固比 | 滤饼含水% | 生产率Kg/(m2·h)(干) |

| 4A沸石 4A zeolite | 80-100 g/L | ≤40 | 262.4 |

| 种分玛瑙种子 | 200-400 g/L | ≤18 | 1094.4 |

| 种分玛瑙成品 | 260-600 g/L | ≤13 | 200 |

| 硅渣white residue | 4.5 | ≤33 | 547.2 |

| 拜尔法氢氧化铝种子 | 400-800g/L | ≤14 | 3200 |

| 脱硫石膏 | 1/1 | <10 | 1280 |

| 拟薄水铝石planned thin water aluminum | 8/1 | 58 | 48 |

| 氧化锌zinc hydroxide | 10/1 | 50.1 | 121.44 |

| 氧化锰还原酸浸矿浆 | 3/1 | 43.06 | 141.536 |

| 磁铁矿 | 2.5/1~4/1 | 6.6 | 800-1600 |

| 硫精矿sulfur concentrate | 4/1~2.5/1 | 10.63 | 576~960 |

| 铜精矿copper concentrate | 4/1~2.5/1 | 11 | 640~960 |

| 全尾矿 | 9/1~4/1 | 20.4 | 4800~800 |

| 精铁矿 | 2/1~1.5/1 | 7~9 | 3200~4800 |

| 锰矿 | 2/1 | 13~15 | 1200~1600 |

| 氢氧化铝 aluminum hydroxide | 4/1 | 13~16 | 560 |

| 五氧化二铝 | 3/1 | 31 | 278.4 |

| 烟煤灰 | 10/1 | 18.7 | 7.8m3/(m2.h) |

| 萤石粉fluorite powder | 2/1 | 10 | 1280 |

| 金精矿gold concentrate | 2/1 | 23~25 | 177.6 |

| 仲钨酸铵 | 2/1 | 70 | 320 |

| 柠檬酸钙(硫酸钙)calcium citrate | 5/1~3/1 | 14 | 412.8 |

| 偶氯有机染料 | 30/1~20/1 | 68 | 160 |

| 烧碱和CuS混合液 | 4/1 | 17.6 | 665.6 |

| ABS树脂 | 10/1 | 34~36 | 272 |

| 磷酸钙矿浆 | 3.5/1 | 20.5 | 552 |

| 溶性磷肥 | 2/1~5/1 | 6~9 | 1600~3200 |

| 硫酸污泥 | 1.5/1 | 35~38 | 1064~1248 |

| 铝钒土 | 5/1~4/1 | 25.4~27 | 2720 |

| 苛化泥 | 4/1 | 45~50 | 425~980 |

| 硫酸铝残硅 | 1.5/1 | 35 | 320 |

| 庆大霉素发酵液 | 1/1~2/1 | 32.1 | 124.5 |

| 粗摒化锌 | 4/1 | 21.5 | 372 |

| 含氟石灰 | 4/1~5/1 | 40~49 | 320~896 |

| 盐铵 | 4/1 | 16~18 | 1600~3000 |

| 硅氟化钠 | 3/1 | 13~18 | 480~800 |

| 湿法水泥 | 2/1 | 15~19 | 1259.2 |

| 选煤精煤 | 4/1 | 21.4 | 348.8 |

| 选煤尾煤 | 6/1 | 23 | 160 |

| 硫酸锌矿浆 | 5/1 | 42~48 | 499.2 |

| 磷石膏(P2OS) | 4/1~5/1 | 18~21 | 1280 |

| 钾长石 | 1~2/1 | 7.9 | 480 |

| 石墨矿灰渣 | 3/1 | 31 | 278.4 |

| 有色金属含锌废浆 | 22.8/1 | 86.18~88 | 118.4 |

| 牛皮渣(硫酸铬) | 44.1/1 | 68 | 120 |

| 白炭黑 | 3% | 80.5 | 150 |

| 水解渣 | 10/1 | 70.2~73.1 | 338.5 |

| 蔗渣 | 10/1 | 74~78 | 480 |

| 柠檬酸(发酵液) | 2.81/1 | 24 | 368 |

| 柠檬酸(钙盐) | 4/1 | 13 | 251.2 |

| 铀冶炼 | 0.6/1~1.3/1 | 16~20 | 667.2 |

| 含锌废浆 | 22.8/~1 | 87.18~89.52 | 216 |

| 硝酸碳肥酸不溶液 | 1.55/1 | 6.8 | 1144 |

| 硫酸铝残渣 | 1.5/1 | 25~44 | 154.56 |

| 硫酸污泥 | 1.5/1 | 35~50 | 1064 |

| 转炉污泥 | / | 20 | 163.2 |

| 荧光材料酸洗 | 2/1 | 28 | 296 |

| 硬脂酸铅 | 5/1 | 58 | 2400 |

| 硝基葸醌 | 4.26/1 | / | 288 |

| 砂料 | 4/1 | 18.2 | 1142.4 |

| 次氧化锌脱砷 碱浸 工艺中的物料 沉砷 |

4/1 10/1 | 42.4 38 | 161.6 354.2 |

| 含钮矿料 | 1.45/1 | 25.4 | 96 |

| 烧结泥渣 | 2/1 | 21 | 132.8 |

| 活性白土 | 4/1 | 49.2 | v |

| 氧化锌悬浮液 | 2.5/1 | 40.3 | 45.12 |

| 黄砂 | / | 4~6 | 1072~1280 |

| 含锌和含铁 白渣 两种悬浮液 黑渣 |

3.5/1 3/1 | 45.1 48.2 | 43.52 36.48 |

| 氨Ⅰ泥 | 2.82/1 | 60~63 | 1080 |

| 色酸AS | 12/1 | 30 | 155.2 |

| 四硝基间甲酚 | 10/1 | 240~340.8 | |

| 磷矿石 | 2/1~1.6/1 | 11 | 1280~1600 |

| 燃煤乙尘灰浆 | 6/1 | 30.3~36.6 | 1257~1544 |

| ABS(丙烯晴-丁二烯-苯乙烯共聚物) | 浆液浓度 10~15 |

38~59 | 生产效率(湿)kg/(m2.h) 160~640 |

| 聚苯乙烯 | 30~50 | 8~14 | 1600~3200 |

| PVA(聚乙烯醇) | 10~15 | 53~62 | 144~192 |

| 硫酸钙 | 30~40 | 14~18 | 800~1600 |

| 金钢砂 | 40 | 6~9 | 2400~3200 |

| 石英 | 15~20 | 6~9 | 1280~1600 |

| 季戊四醇 | 20~25 | 22~38 | 188~345 |

| 化学品 Chemicals |

4A沸石 4A zeolite |

催化剂 catalyzer |

矿物 Mineral |

氢氧化铝 aluminum hydroxide |

钾盐 potassium salt |

食品 Food |

醋酸 ethylic acid |

肥料 Fertilizer |

磷石膏 phosphogypsum |

| 玛瑙填料 agate filler |

染料及其中间体dyes and intermediates | 煤的泥浆 coal slurry |

支链淀粉衍生物amylopectin derivative | 磷酸氢钙 calcium bicarbonate |

|||||

| 氟化铝 aluminum fluoride |

工业洗涤剂industrial detergent | 铜的浓缩物 copper concentrate |

柠檬酸钙 calcium citrate |

碳酸钙 calcium carbonate |

|||||

| 氧化铝凝胶alumina gel | 氧化铁 Iron oxide |

黄金的沉淀物 gold sediment |

草酸钙 calcium oxalate |

硫酸钙 sulfate calcium |

|||||

| 氢氧化铝 aluminum hydroxid |

氧化铝 alumina |

钛铁矿 ilmenite |

硫酸钙 sulfate calcium |

硝酸钙 nitrate nitrate |

|||||

| 磷酸铝 aluminum phosphate |

锌钡白 Charlton white |

氢氧化镁magnesium hydroxide | 谷氨酸 glutamic acid |

硝酸法的泥浆phosphorus method mud | |||||

| 硫酸铝 aluminum sulfate |

碳酸镁magnesium carbonate | 碳酸锰 manganese carbonate |

蔗糖 sucrose |

环境保护 Environmental protection |

工业废水 Industrial wastewater |

||||

| 氨基酸 amino acids |

氢氧化镁magnesium hydroxide | 矿石沥滤残渣mineral drain filter residue | 柠檬酸 citrate |

城市污水 municipal sewage |

|||||

| 钡盐 barium salts |

镍盐 nickel salt |

磷酸盐 phosphate red mud |

乳酸 lactic acid |

除尘污泥 dust removal sludge |

|||||

| 硼酸盐 borates |

过氧化物 peroxide |

金红石rutile | 麦芽糖 malt sugar |

粉煤灰 fly ash |

|||||

| 硼酸 bromine borate |

磷酸 ortho-phosphoric acid |

银的回收物silver | 蛋白质 | 碳黑水 carbon black water |

|||||

| 溴盐 bromide salt |

涂料 coating material |

钛矿的分解物titanium mineral decomposition | 植物油 | ||||||

| 锌盐 zinc salt |

增塑剂 plasticizer |

二氧化钛titanium dioxide |

手机:13361303111

电话:0535-2132537

邮件:brxsb@yantaibairun.cn

地址:山东省烟台市福山区福桃路2808号