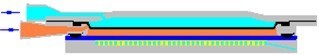

| 1) 过滤阶段:当过滤板框关闭后,料浆经过料浆管被泵入滤腔。滤液透过滤布进入滤液腔,再经滤液软管到达滤液总管后排出;同时,滤腔内形成滤饼。 1) Filtration stage: When the filter plate frame is closed, the slurry is pumped into the filter chamber through the slurry tube. The filtrate enters the filtrate chamber through the filter cloth, and then exits the filtrate main pipe through the filtrate hose. At the same time, the filter cake is formed in the filter chamber. |

过滤阶段Filtration stage |

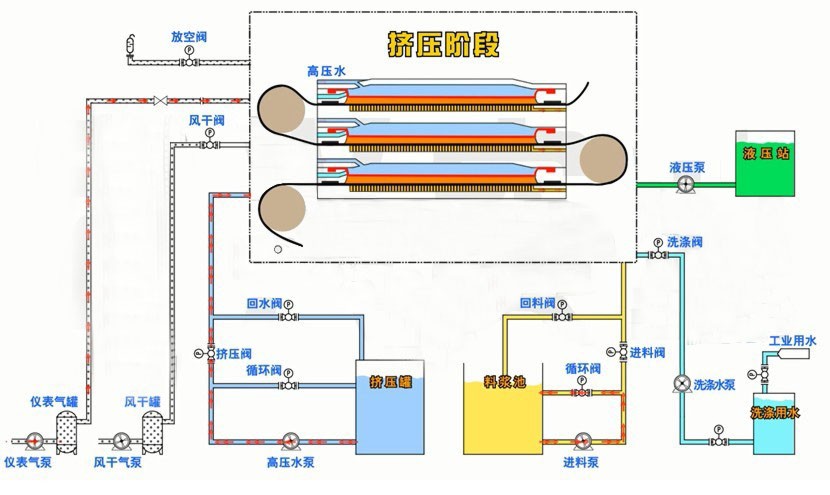

| 2) 挤压阶段:高压水通过高压水软管进入隔膜上腔,使隔膜向滤饼挤压,从而将滤饼中的液体挤出。 2) Extrusion stage: High-pressure water enters the upper chamber of the diaphragm through the high-pressure water hose, so that the diaphragm is squeezed to the filter cake, and finally the liquid in the filter cake is squeezed out. |

挤压阶段Extrusion stage |

| 3) 洗涤阶段:洗涤液经过料浆管被泵送到过滤腔;再穿过滤饼和滤布后流入排放管 3) Washing stage: The washing liquid is pumped to the filter chamber through the slurry tube; Then it passes through the filter cake and filter cloth into the discharge pipe. |

洗涤阶段Washing stag |

| 4) 空气干燥:通过滤饼的气流携带水气,最大限度降低滤饼水份,同时排空滤液腔。 4) Air drying: The air flow through the filter cake carries water, minimizes the filter cake moisture, and emptying the filtrate chamber. |

|

| 5) 滤饼排放:当干燥过程完成后,组件打开,驱动机构带动滤布运行,滤饼随布从两边卸出。 5) Filter cake discharge: When the drying process is completed, the component is opened. The driving mechanism drives the filter cloth to run, and the filter cake is discharged from both sides with the cloth. |

|

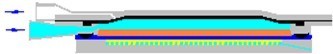

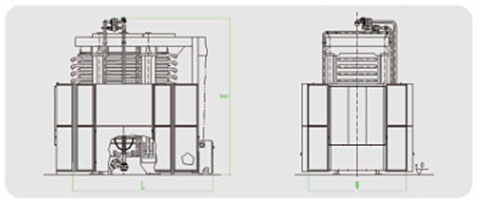

| 1 底压板 2 立柱 3 快速反应缸 4 顶压板 |

5 上层框架 6 滤布输送装置和滤饼槽 7 板框组 8 辊子 |

9 管路 10 导向块 11 液压装置 12 控制柜 |

13 阀门 14 滤布 16 液压管路 17 侧保护罩和维修平台 |

| 型 号 | 过滤面积 (m2) | 外形尺寸( L×W×H)(m) | 滤框数量 (块) | 重 量 (吨) |

| HVPF-1 | 1 | 2.5×1.5×2.0 | 2 | 6 |

| HVPF-2 | 2 | 2.5×1.5×2.2 | 4 | 7 |

| HVPF-3 | 3 | 3.65×2.5×2.2 | 2 | 11 |

| HVPF-6 | 6 | 3.65×2.5×2.3 | 4 | 12 |

| HVPF-9 | 9 | 3.65×2.5×2.5 | 6 | 13 |

| HVPF-12 | 12 | 3.65×2.5×2.7 | 8 | 14 |

| HVPF-15 | 15 | 5.1×3.0×3.0 | 6 | 28 |

| HVPF-20 | 20 | 5.1×3.0×3.3 | 8 | 29 |

| HVPF-25 | 25 | 5.1×3.0×3.7 | 10 | 32 |

| HVPF-30 | 30 | 5.1×3.0×4.1 | 12 | 33 |

| HVPF-35 | 35 | 5.1×3.0×4.5 | 14 | 34 |

| HVPF-40 | 40 | 5.1×3.0×4.8 | 16 | 38 |

| HVPF-45 | 45 | 5.1×3.0×5.2 | 18 | 39 |

| HVPF-50 | 50 | 5.1×3.0×5.6 | 20 | 40 |

| HVPF-55 | 55 | 5.1×3.0×5.9 | 22 | 41 |

| HVPF-60 | 60 | 6.8×5.0×4.2 | 10 | 62 |

| HVPF-72 | 72 | 6.8×5.0×4.6 | 12 | 65 |

| HVPF-84 | 84 | 6.8×5.0×4.9 | 14 | 72 |

| HVPF-96 | 96 | 6.8×5.0×5.3 | 16 | 74 |

| HVPF-108 | 108 | 6.8×5.0×5.7 | 18 | 81 |

| HVPF-120 | 120 | 6.8×5.0×6.0 | 20 | 84 |

| HVPF-132 | 132 | 6.8×5.0×6.4 | 22 | 90 |

| HVPF-144 | 144 | 6.8×5.0×6.7 | 24 | 93 |

| HVPF-156 | 156 | 6.8×5.0×7.1 | 26 | 99 |

| HVPF-168 | 168 | 6.8×5.0×7.3 | 28 | 102 |

|

物料名称 Material name |

粒径分布 |

给料浓度% |

处理量kg(m2h) |

滤饼水分% |

矿源 |

|

焙烧金尾矿 |

-200目90%左右 |

30-35 |

350-400 |

14-18 |

河南 |

|

浮选金尾矿 |

-200目90%左右 |

20-30 |

300 |

18 |

栖霞 |

|

炉渣铁 |

-200目90% |

40 |

280 |

≤9 |

包钢 |

|

硫酸钙 |

废酸经石灰中和 |

10 |

200-250 |

35-40 |

河南 |

|

污泥 |

城市化工 |

5 |

100 |

65-70 |

烟台 |

|

煤泥 |

-325目90% |

30-35 |

300 |

16-17 |

河南 |

手机:18906458967

电话:0535-2132537

邮件:brxsb@yantaibairun.cn

地址:山东省烟台市福山区福桃路2808号